Steel frame fix out can be a slog, what if we told you Paslode had new steel frame brads that changed that…

Tradie Tough Test: Paslode’s Steel Frame Brads

For this test, The Tradie caught up with carpenter Jesse Mintron from Pillar Construction Group in Brighton to Melbourne’s east. He typically works on high-end homes in the area, and does a lot of steel framing and steel frame fix out. We were also lucky to be joined by the brains behind the Steel Frame Brads – Paslode Product Development Engineer Shane Anthony. He took us through what made these brads so special, and why they’re now a massive asset to Jesse’s work.

TEST #1: ABSOLUTE TIMESAVER

Traditionally, Jesse and other carpenters have had to complete numerous and tedious tasks when it comes to fixing trim to steel frame out. From pre-marking or pre-drilling, to breaking out the glue – this can take a tonne of time and drain productivity. The Paslode Steel Frame Brads cut a tonne of this stuff out, pure and simple. “With traditional jobs, there was a lot of gluing and screwing,” Jesse said. “It’s been quite time consuming, a pain in the bum really.

“With these brads, there’s been none of that. We just shoot them in and they work a treat.” Shane said head to toe, the design of these brads was done with the everyday tradie in mind. Of course, having all of these pluses piled into one nail not only saves time, but is friendly on the wallet too.

“The issue builders and carpenters have when fixing into steel is they have to glue along the board of the trim because the current brads on the market don’t have great holding power on them for steel,” he added. “As you can imagine, those options are time consuming and costly. So, we’ve developed these Steel Frame Brads to simplify that installation process.”

TEST #2: POWER AND PASSION

As well as saving a tonne of time, Paslode Steel Frame Brads are more secure than their traditional counterparts.

“You’ll notice right away the red resin,” Shane said. “This is specially designed to actively glue and hold extremely well in the steel.” “We’ve left the head quite small. We’ve done that intentionally to create a clean and aesthetic finish in the trim boards.”

Shane added that due to their design, these brads can penetrate two layers of steel should they need to. While Jesse does a tonne of fix outs on steel framing, he used the brads on this site to secure timber moulds to steel battens.

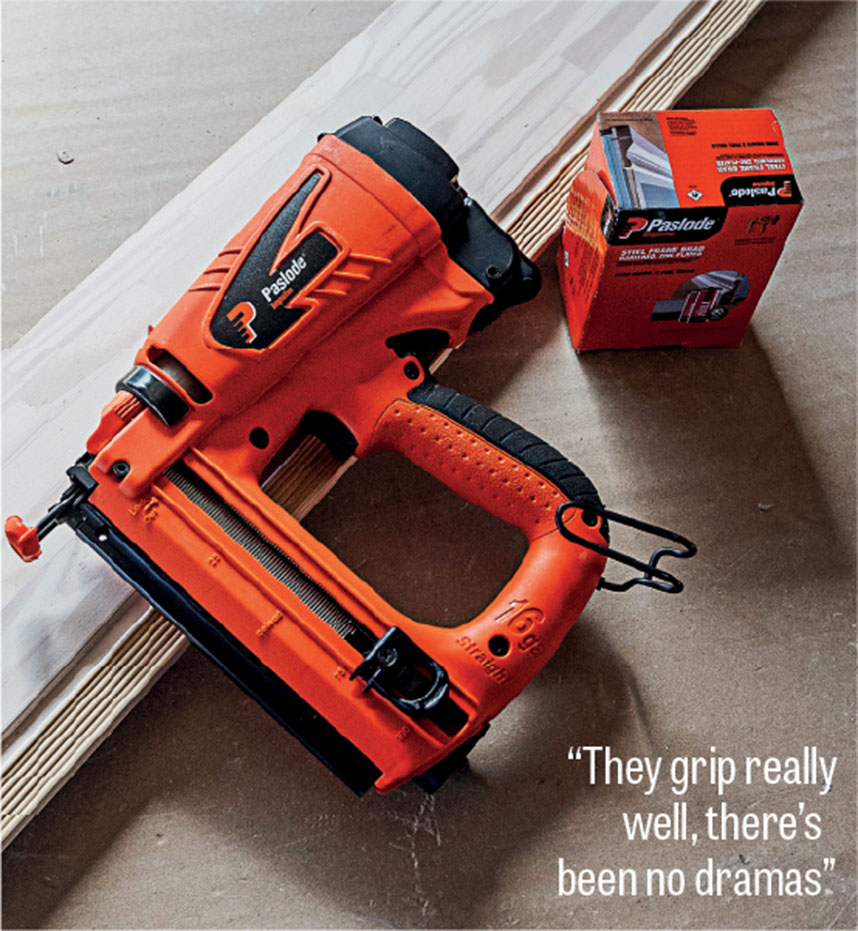

“They grip really well, there’s been no dramas. I can tell these will hold up,” he said. Jesse used Paslode’s Straight TrimMaster for this test – Shane said it was the perfect cordless tool for driving Steel Frame Brads.

“It makes tradies’ lives a whole lot easier because if they don’t have power on-site, they can easily pull out the Cordless Straight TrimMaster.”

HIT THE NAIL ON THE HEAD

Paslode doesn’t waste your time with these new Steel Frame Brads. They’re fantastic in every sense of the word, whether it’s saving you time, or delivering a high-quality final product. The brads come in 38mm and 45mm lengths for all your interior finish applications.

For optimum performance, use Paslode’s Steel Frame Brad with the latest TrimMaster model.

For more information on the Paslode Steel Frame Brad see paslode.com.au/product/steel-frame-brad.